Tire shredder

Product Introduction

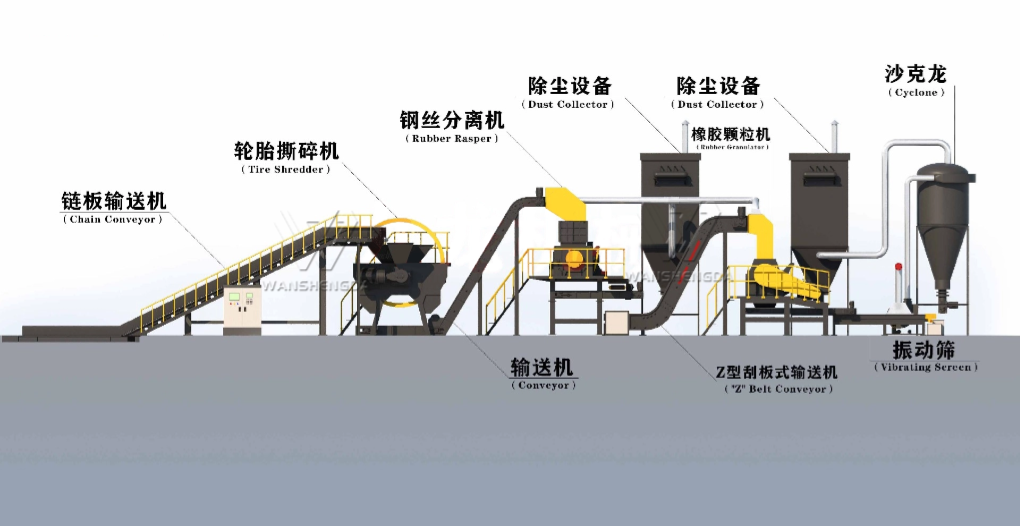

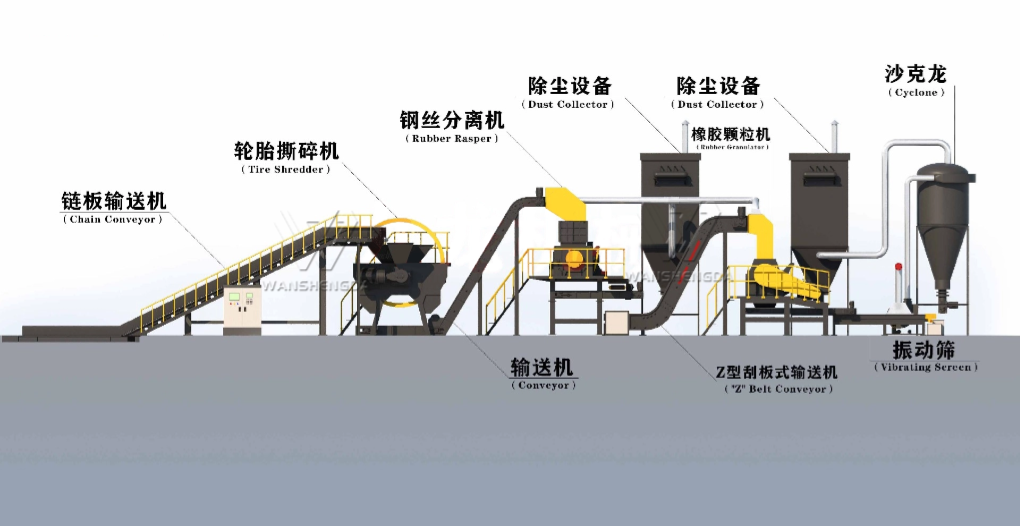

Waste tire processing equipment is a large-scale complete set of equipment that can separate the three raw materials of rubber, steel wire and fiber contained in tires at one time at room temperature to achieve high recycling. The process is perfect and the production is efficient

High rate. The waste tire processing production line can recycle tires with diameters ranging from 400 to 3000mm according to customer requirements. It has strong applicability, and the output size can be controlled within the range of 5 to 100mm, with high output

It can reach 200- 10,000 kg/h. This production line operates at room temperature and does not require any chemical additives, thus not causing secondary pollution to the environment. The production line adopts a PLC control system for operation

It is easy to maintain and features low energy consumption and a long service life.

Main equipment

Depending on different tire characteristics and productivity requirements, the equipment may include:

1. Fully automatic wire drawing machine: Remove the bead.

2. Conveying equipment: Conveyor belts, screw conveyors and pneumatic conveying systems.

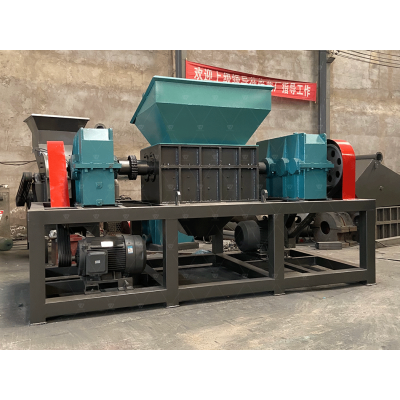

3. Tire shredder: Shred tires into sheets (50mm-150mm).

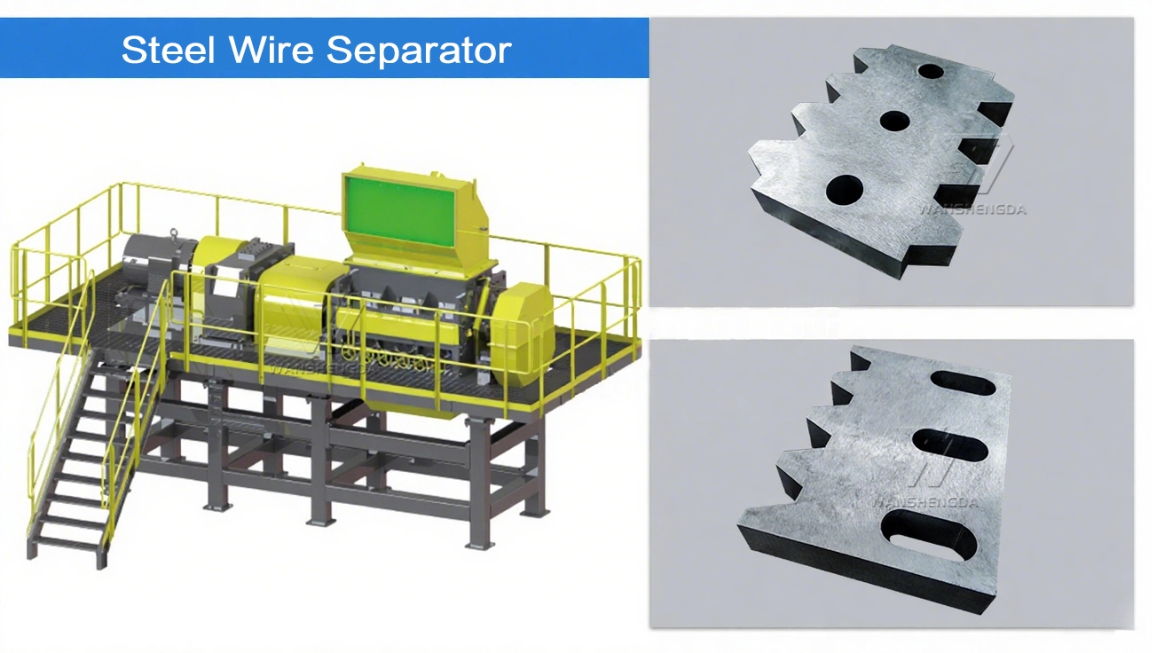

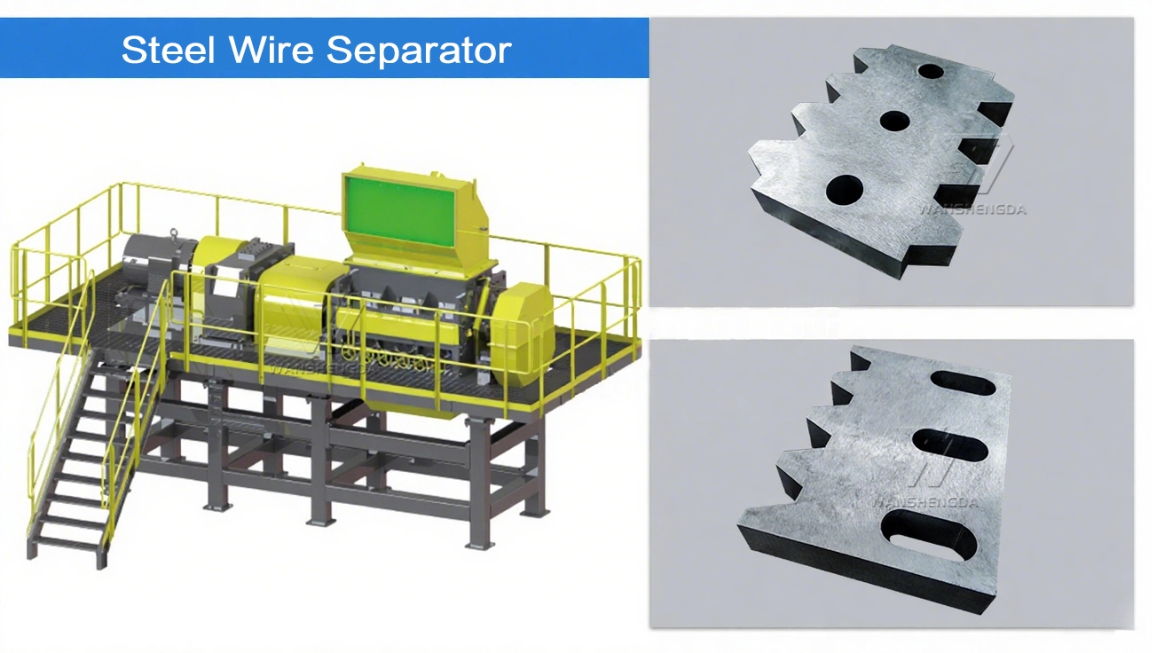

4. Steel wire separator: It separates rubber from steel wire and processes it into rubber particles (10mm-20mm).

5. Magnetic separator: Separates steel wires from the mixture of rubber and steel wires.

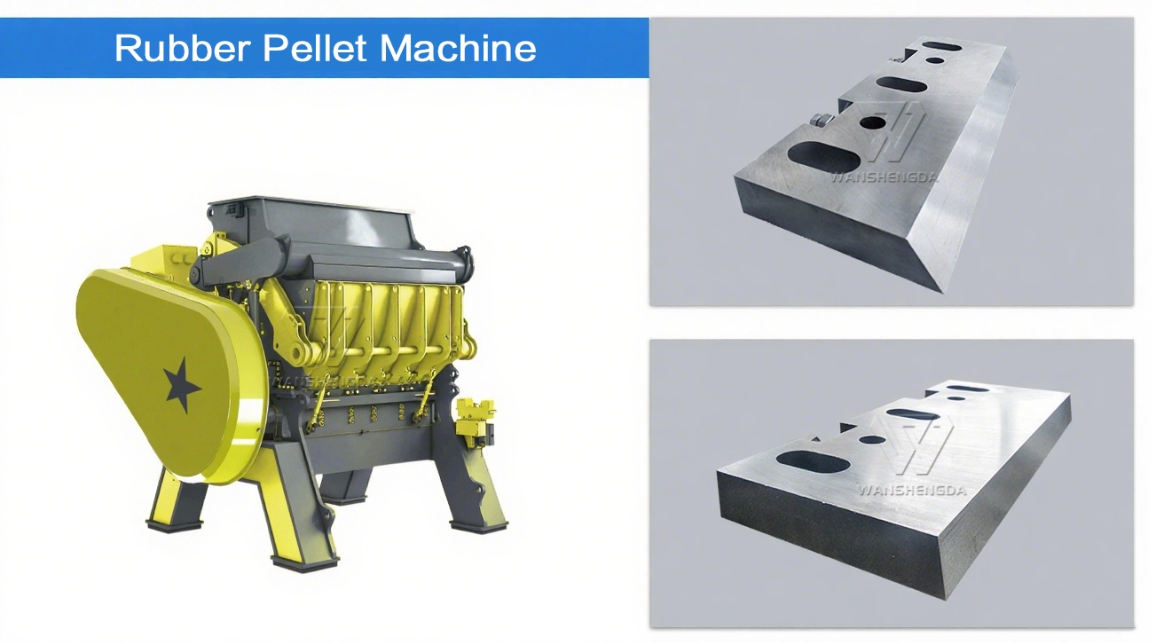

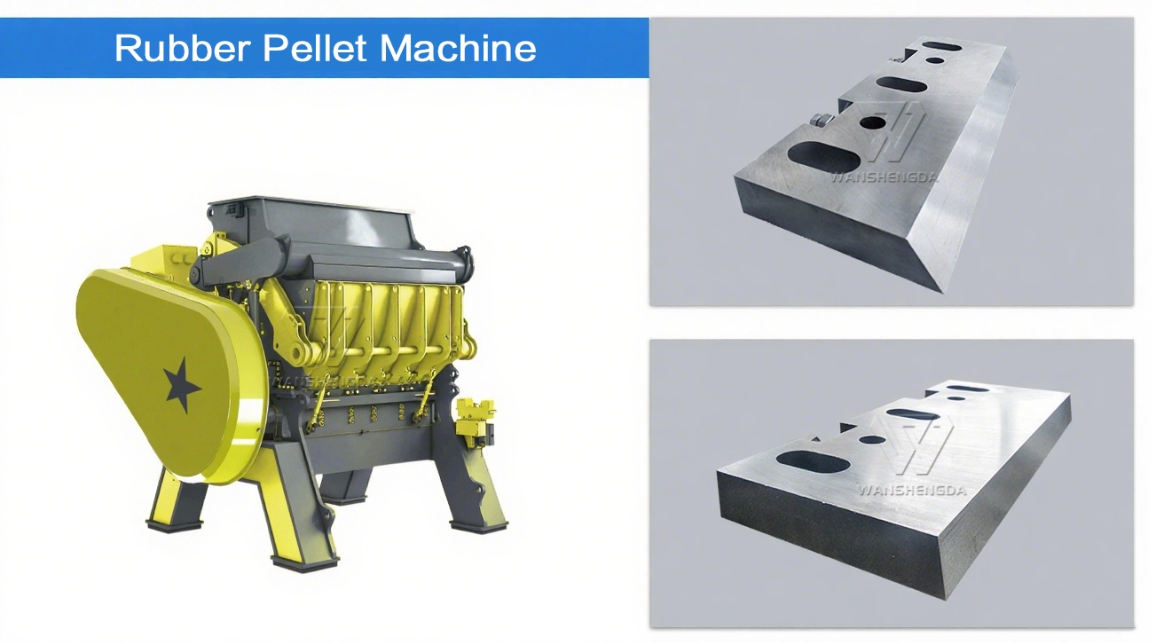

6. Rubber granulator: Crushes rubber particles into smaller sizes (1mm-7mm).

7. Vibrating screen: It sorts rubber particles of different sizes, and the super-large particles are sent to the crusher for secondary crushing.

8. Fiber separator: It is used to remove foreign substances and fibers.

9. Secondary magnetic separator: Remove any remaining fine steel wires.

10. Grinding mill: Grind particles into powder (30 mesh - 100 mesh).

11. Fully automatic bagging system: Load the finished products into storage bags or packaging bags.

This equipment is a supporting device in the complete set of tire recycling equipment production line. It can be matched according to the special requirements of users for the finished products. The fineness of the finished product after matching can reach 120 mesh, which can be adjusted according to the fineness

Adjustments are required.

Production line features

1. The entire tire can be directly inserted without pre-crushing or pulling the rims.

2. From the entire tire to 1-7mm particles, the entire production and packaging process has no secondary handling intermediate links.

With a processing capacity of up to 5000kg/h, all on-site operations can be completed by just 7 people.

4. The equipment model can be configured according to the production requirements of customers, ranging from 200kg/h to 10000kg/h, offering a wide range of choices.

5. The fully combined two-layer structure makes installation, replacement and maintenance more convenient.

6. Seamless connection, full-process smoke and dust monitoring.

7. Before leaving the factory, each machine should undergo an 80-100 hour feeding test to ensure stable performance.

8. CE certification, unified standards, emphasis on technology.

Product advantages

Bearing design: Reinforced design and semi-open structure make maintenance easier. It is equipped with a dust-proof baffle to extend the service life of the bearings

Screen design: Control the size of the material. By feeding it into a shredder for repeated crushing, the output is controlled within the specified size range

Body design: The blades are sturdy and wear-resistant. The blade arrangement and meshing method are specially designed for waste tires.

Power design: Driven by a reduction motor, it saves time, effort and electricity, and has strong power.

Environmental protection design: The equipment features low speed, high torque, low noise, and low dust, meeting environmental protection standards.

The production of recycled rubber

Tire reproduction. Chemical desulfurization of waste tire rubber to produce rubber is an ancient method for comprehensive utilization of waste tires. The current production technology for recycling and reusing waste tires is

A reasonable, scientific and widely applied approach has been adopted by countries all over the world.

Produce vulcanized rubber powder

The powder production industry has huge development potential. Due to the use of pure physical methods for treatment, there is no pollution from waste gas or wastewater during production, and the resource utilization rate is very high. This is a recognized form of recycling and being free

Methods for hazardous treatment of used tires.

Pave the road with waste tires

New technology, new life. Waste tires used for paving roads are called rubber asphalt. This new method of recycling used tires originated in the United States in the 1960s - processing used tires into rubber

Powder is added to asphalt as a modifier.

Solid waste fuel

The embodiment of light and heat. Waste tires are high calorific value materials. Their calorific value per kilogram is 69% higher than that of wood, 10% higher than that of bituminous coal, and 4% higher than that of coke. After crushing the waste tires, they are mixed with various combustible wastes

The materials are mixed in the required proportion to make solid waste fuel (RDF), which can be injected

It can be put into blast furnaces to replace coal, oil and coke as fuel for burning cement, or to replace coal and thermal power generation. Meanwhile, this method also generates a by-product - carbon black. After activation, carbon black can be used as a supplement

Strong agents are used in the production of rubber products.

Refining of waste tire oil

The waste tire oil refining equipment converts waste tires into 45-52% pyrolysis oil, 30%-35% carbon black and 10-15% steel wire through high-temperature pyrolysis. These pyrolysis oils can be used in cement plants and glass

Heavy industries such as factories and boiler factories. Carbon black can be used in cement plants and pressed into balls for sale.

Scrap tires

It is one of the main ways to convert it into energy and non-rubber resources. The main methods include catalytic pyrolysis, high-temperature pyrolysis and low-temperature pyrolysis. Waste tires can be used to extract steel, carbon black and stone at high temperatures

Oil, natural gas, etc. One ton of waste tires can be recycled into 35 kilograms of carbon black and 55 kilograms of fuel oil.

| Model |

Spindle power (kw |

Spindle speed (r/min) |

Output (t/h |

Conveyor power (kw) |

Number of cutter heads (pieces) |

Cutter head diameter (m/m) |

Crushing size (am |

Hull dimensions (m |

Length, width, height (meters) |

Weight (t |

| wsd - 2600 |

4-160*2 |

16-18 |

25-60 |

4-3kw |

40 |

Ø 720 |

3-10 |

2.5*14 |

8 2*4*4 3 |

36 |

| wsd - 1900 |

4-90*2 |

14-16 |

10-25 |

4-3kw |

40 |

Ø 560 |

3-10 |

23*2 |

8*2.5*2.4 |

15 |

| wsd - 1500 |

4-45*2 |

14-16 |

8-18 |

4-3kw |

30 |

Ø 530 |

3-10 |

2*2 |

4*1.7*2.4 |

12 |

| wsd - 1200 |

4-37*2 |

18-20 |

6-15 |

Not one |

28 |

Ø 372 |

3-10 |

14*1 |

3.2*2*1.9 |

6 |

| wsd - 1000 |

4-30*2 |

18-20 |

5-10 |

Not one |

30 |

Ø 360 |

3-10 |

1.2*1 |

3*2*19 |

5 |

| wsd - 600 |

4-15*2 |

18-20 |

2-5 |

Not one |

26 |

Ø 260 |

3-10 |

0.82*0.9 |

2.6*2*1.9 |

2.5 |