- Home

-

Products

Scrap Recycling Equipment Series

- Metal Chip Briqueting Machine

- Vertical Metal Briquetting Machine Production Line

- Horizontal Metal Chip Briquetting Machine

- Metal chip crushing degreasing and briquetting production line

- Hydraulic Metal Baling Machine

- Non-Metallic Vertical Baler

- Non-metallic horizontal baler

- Automatic Hopper Type Metal Balers

- Stainless steel scrap baling machine

- Stainless steel refining cylindrical baling machine

- Straw Baler

- Metal crusher

- Pig Iron Crusher

- Hydraulic Scrap Metal Shearing Machine

- Hydraulic tiger head shearing machine

- Hydraulic Crocodile Chearing Machine

Shredder Equipment SeriesWoodworking Machinery SeriesMining Equipment Series- Jaw Crusher

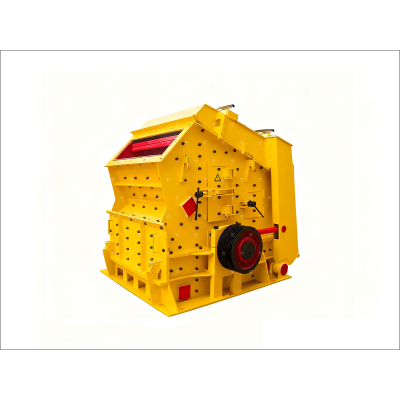

- Impact Crusher

- Cone crusher

- Hammer crusher

- Tire-Mobile Jaw Crushing Station

- Tire-Mounted Mobile Cone Crushing Station

- Tire-Mobile Impact Crushing Station

- Tire-Mounted Mobile Vertical Shaft impact Crusher Station

- Tire-Mobile Screening Station

- Track - Mounted Mobile Jaw Crushing Station

- Track -Mobile Cone Crushing Station

- Track-Mobile Impact Crushing Station

- Track- Mobile Screening Station

Grinding Mill Equipment Series -

Hot

Top sale

- Metal Chip Briqueting Machine

- Metal Chip Briquette Production Line

- Vertical Metal Briquetting Machine Production Line

- Horizontal Metal Chip Briquetting Machine

- Hydraulic Metal Baling Machine

- Automatic Hopper Type Metal Balers

- Metal Shavings Shredder

- Metal chip crushing degreasing and briquetting production line

- Company

- Customers

- Resources

- Contact Us

Menu

Scrap Recycling Equipment Series

- Metal Chip Briqueting Machine

- Vertical Metal Briquetting Machine Production Line

- Horizontal Metal Chip Briquetting Machine

- Metal chip crushing degreasing and briquetting production line

- Hydraulic Metal Baling Machine

- Non-Metallic Vertical Baler

- Non-metallic horizontal baler

- Automatic Hopper Type Metal Balers

- Stainless steel scrap baling machine

- Stainless steel refining cylindrical baling machine

- Straw Baler

- Metal crusher

- Pig Iron Crusher

- Hydraulic Scrap Metal Shearing Machine

- Hydraulic tiger head shearing machine

- Hydraulic Crocodile Chearing Machine

Shredder Equipment Series

Woodworking Machinery Series

Mining Equipment Series

- Jaw Crusher

- Impact Crusher

- Cone crusher

- Hammer crusher

- Tire-Mobile Jaw Crushing Station

- Tire-Mounted Mobile Cone Crushing Station

- Tire-Mobile Impact Crushing Station

- Tire-Mounted Mobile Vertical Shaft impact Crusher Station

- Tire-Mobile Screening Station

- Track - Mounted Mobile Jaw Crushing Station

- Track -Mobile Cone Crushing Station

- Track-Mobile Impact Crushing Station

- Track- Mobile Screening Station

Grinding Mill Equipment Series

- Metal Chip Briqueting Machine

- Metal Chip Briquette Production Line

- Vertical Metal Briquetting Machine Production Line

- Horizontal Metal Chip Briquetting Machine

- Hydraulic Metal Baling Machine

- Automatic Hopper Type Metal Balers

- Metal Shavings Shredder

- Metal chip crushing degreasing and briquetting production line

.png)